Hubei Aojun New Energy Technology Co., Ltd. is committed to improving and upgrading China's logistics equipment manufacturing technology, product technology and intelligent technology. It is a high-tech enterprise focusing on creating three major business segments: intelligent manufacturing, energy equipment and logistics equipment, integrating R&D, manufacturing, sales and service.

Determined to rank among the industry leaders, empowering all employees' growth through an ecological foundation. Building a community with a shared future, where every participation generates value and all parties progress together.

Enhancing industrial capabilities through exquisite craftsmanship, dedicated to technological innovation and paradigm reform, committed to promoting industrial development, breaking industry barriers, and reshaping development patterns.

Cultivating the soil for cooperation with virtue, catalyzing mutual progress with wisdom. Gathering collective wisdom through mutual trust, pursuing excellence through win-win cooperation, and building a community of growth with warmth.

Aojun New Energy focuses on three core business areas, providing customers with comprehensive solutions

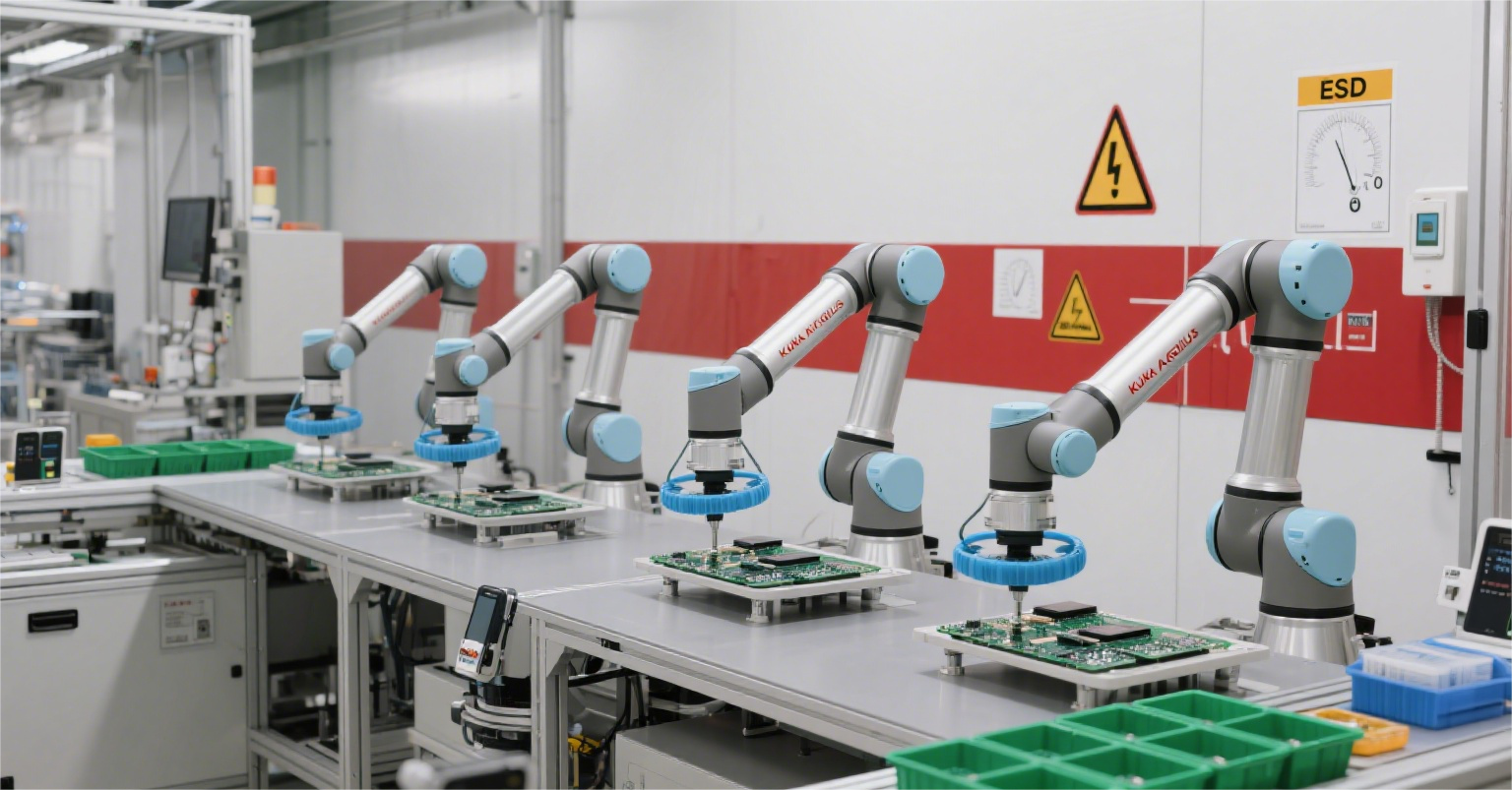

Industrial robots, non-standard automated production lines, lean production full-process improvement and reconstruction, workshop online logistics transportation and warehousing.

Passenger car workshop parts logistics turnover equipment, truck workshop parts logistics turnover equipment, other types of non-standard customized workshop logistics turnover equipment.

Gasoline transportation and storage equipment, natural gas transportation and storage equipment, hydrogen transportation and storage equipment.

Aojun's cooperative projects cover six major fields, providing customers with comprehensive solutions. Below are the project and product showcases.

Tank Baffle Robot Welding System

(Including Visual Laser System)

(Including Visual Laser System)

Robot Spraying System, capable of spraying all six sides of the tank without dead ends. Suitable for surface spraying of all types of containers.

Welding irregularly shaped tanks

Welding gooseneck dish-shaped tanks

Simultaneous welding on left and right sides of the common rail

Welding circular and square tanks

Welding refrigerated container T-floors

Customized welding positioning device

High-efficiency cleaning equipment for industrial pipelines with adjustable pressure settings

Fully automated surface treatment line with corrosion-resistant materials

Food-grade cleaning solution with multi-stage filtration system

Precision mixing equipment with automatic proportion control

ISO-compliant storage solution with safety monitoring functions

Detection safety system with real-time monitoring and automatic alarm functions

High-efficiency air purification equipment for painting workshops

Automatic walking system + material level identification system

With sheet alignment and placement angle adjustment functions

180° left and right rotation, hydraulic clamping, automatic feeding

Tank container welding production line, integrating positioning, rotation, and welding. Can rotate 270° clockwise and 180° counterclockwise. Can be custom-made.

A Circular Seam Welding Device for Special-Shaped Tank Production Robot Workstation

Industrial Robot Adaptive Control Program System

A Cantilever Five-Gun Circular Seam Laser Tracking Welding Workstation with Flip Positioner